A Brief Discussion on Common Sealing Techniques

PREFACE

The anodizing of aluminum alloys for construction, decoration, and protection is basically the production of porous anodized films. The structure of porous anodized films consists of two parts: a barrier layer that adheres closely to the metal substrate and a porous layer.

Although this porous property gives the ability of anodized films coloring and other functions, its corrosion resistance, weather resistance, and pollution resistance cannot meet the requirements for use. The micropores of the aluminum anodic oxide film must be sealed. The unsealed anodic oxide film, due to the large number of micropores, increases the effective surface area of the workpiece or sample exposed to the environment by tens to hundreds of times, and the corresponding corrosion rate also increases significantly.

In order to improve the corrosion resistance, pollution resistance, and light and weather resistance of aluminum alloys after anodizing treatment, sealing technology has become a very important technical link.

Introduce several common sealing techniques, their principles, characteristics, advantages and disadvantages,as well as our company's sealing products.We focus on the popular product of nickel free and fluorine free medium temperature sealing agents.

Common sealing methods

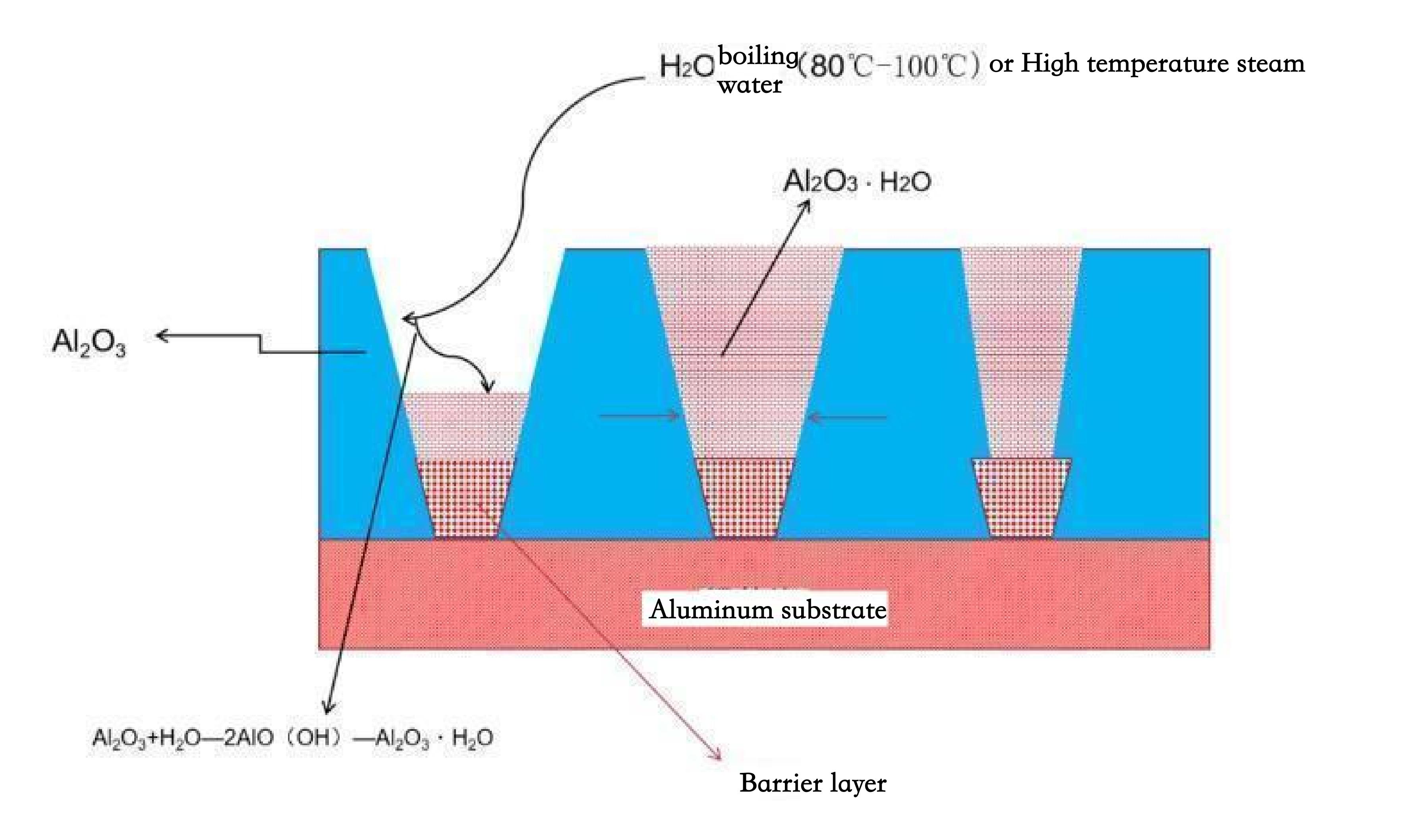

Hydration blocking

Figure: Schematic diagram of hydration blocking reaction

① Boiling water sealed

Principle: Oxide film - deposited hydrated oxide film - pseudo boehmite - crystallized to form boehmite

Equation: Al2O3+H2O -2AlO (OH) - Al2O3 · H2O (Boehmite)

Features: Convert the oxide film into a crystalline, non adsorption film with simple process operation.

Disadvantages:

1. High requirements for water quality, even trace pollution can lead to the failure of hydration sealing reaction.

2. Easy to frost (Al2 (SO4) 3).

② High temperature steam sealing

Principle: Oxide film - deposited hydrated oxide film - pseudo boehmite - crystallized to form boehmite

Equation: Al2O3+H2O -2AlO (OH) - Al2O3 · H2O (Boehmite)

Features: Not affected by water quality, pH, etc., good sealing quality, not easy to frost.

Disadvantages: Pressure vessel equipment has high costs and cannot continuously process large aluminum materials.

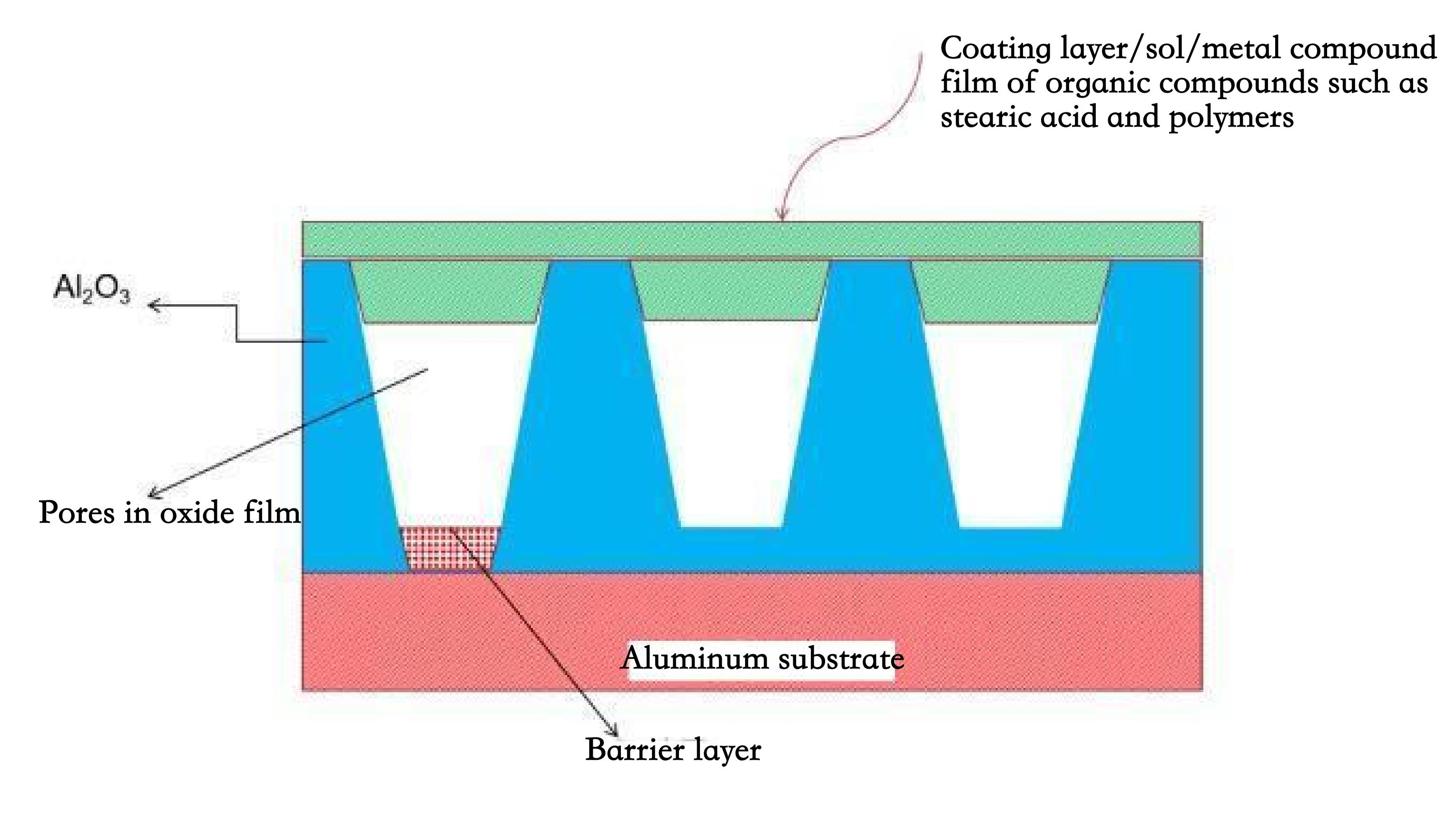

Organic closure

Principle: Apply organic substances such as stearic acid and polymers onto the surface of the oxide film, and dry it at high temperature for a long time.

Features: Good electrical insulation performance and excellent corrosion resistance.

Disadvantages: The mechanical strength of the film layer is insufficient, and most processes cannot be industrialized due to process conditions.

Sol sealing

① Silica sol sealing

Principle: Use inorganic or organic silicon as a precursor to react with hydroxyl groups on the surface of the oxide film.

Characteristics: Excellent corrosion resistance after sealing and film formation.

Disadvantage: Insufficient mechanical strength.

② Aluminum sol sealing

Principle: After immersing and drying the Boehringer Ingelheim sol, the physical substance is adsorbed and filled into the pores of the oxide film.

Features: Corrosion resistance is better than sealing with boiling water.

Disadvantages: Expensive price, insufficient wear resistance and hardness.

Metal salt sealing

① Dichromate sealing

Principle: 2Al2O3+K2Cr2O7+5H2O -2Al (OH) CrO4+2Al (OH) 3+Cr2O7+KOH

Disadvantages: After sealing, the sealing film appears yellow, with a limited range of use. Chromium is not environmentally friendly and belongs to carcinogens.

② Metal salt deposition sealing

Room temperature nickel salt sealing

Principle: F - (adsorption) oxide film pores - (promotion) Ni2+- (deposition) film pores - (hydrolysis filling) Ni (OH) 2

Features: Simple preparation, easy operation, low energy consumption during room temperature operation.

Medium temperature nickel salt sealing

Principle: Hydrated oxide film - Boehmite - Ni (OH) 2- Co deposition

Features: Simple preparation, easy operation, no fluorine will cause F-corrosion in the inner cavity, excellent sealing effect.

Sealing with alkaline earth light metal salts

Principle: Alkaline earth light metal ions deposit in the pores of the oxide film to form MN+/Al composite compounds.

Features: Easy to operate, environmentally friendly. Wastewater treatment is simple.

③ Metal film sealing

Principle: Generate a metal compound film and cover the surface of the oxide film.

Features: Simple preparation, easy operation, and the film layer is not dense enough.

Figure: Schematic diagram of organic matter/sol/metal film closure

Sealing process products

LW-08 is a light green solid powder which has stable sealing quality as well as the following characteristics:

1. The solution has excellent resistance to impurities.

2. Wider operating range: temperature required to 20-35℃, even at 15℃ can achieve good

sealing effect if extend the sealing time; running water can be used for bath make-up.

3. Easy to operate: The solution is of good buffering capacity to acid and alkali. It’s no need to adjust the PH frequently. And the consumption of F- and Ni2+ keeps good balance.

4. Excellent capacity of anti-sealing bloom.

5. Silver white aluminum profiles can keep color well after sealing.

LW-10 Medium Temperature Sealing Additive

LW-10 is a reddish brown to brown liquid which is for aluminum profiles oxidation film sealing treatment, the sealing quality is stable and of wide application range, the profile surface texture is superior after sealing treatment.

Characteristics:

1) Fast sealing speed: for thick oxidation film aluminum profiles (15-20μm), 13-15 mins is enough for sealing.

2) Excellent anti-sealing bloom capacity: LW-10 contains high polymer ash inhibitor, even in high temperature and high PH value is not easy to form bloom.

3) No iridescence and no color fading for black aluminum profiles.

4) Especially suitable for aluminum solar frame products.

LW-50 Medium Temperature Sealing Additive

LW-50 is a light green powder which is for aluminum profiles oxidation film sealing treatment.

Characteristics of LW-50 Medium Temperature Sealing Agent:

1) After sealing, no sealing bloom.

2) Improve the surface gloss of aluminum profiles.

3) Film can be sticked right after sealing process, and not glutinous.

4) Improve the aluminum profiles resistant to acid and alkali capacity and anti-secondary pollution capacity.

5) Solution is stable and easy to operate.

LW-66 Fast Speed Medium Temperature Sealing Additive

LW-66 is a light green powder which is for aluminum and aluminum alloy anodized film sealing treatment, especially suitable for sealing dyed products after oxidation.

Characteristics of LW-66 Rapid Medium Temperature Sealing Agent:

1) After sealing, no sealing bloom and no color shade.

2) Improve the surface gloss of aluminum profiles.

3) Film can be sticked right after sealing process, and not glutinous.

4) Improve the aluminum profiles resistant to acid and alkali capacity and anti-secondary pollution capacity.

5) Solution is stable and easy to operate.

Hot selling sealing products

Since the 1990s, the application of medium temperature sealing, including new medium temperature sealing processes without nickel and fluorine, has gradually expanded from the laboratory to large-scale production, considering environmental protection and energy conservation. In addition to the three types of medium temperature sealing products, LW-10 medium temperature sealing agent (liquid), LW-50 medium temperature sealing agent (solid), and LW-66 rapid medium temperature sealing agent (solid), Haihua Technology also has LW-99 nickel free and fluorine free medium temperature sealing agent.

LW-99 Nickel-free and Fluoride-free Medium Temperature Sealing Additive

LW-99 is a kind of colorless or light amber transparent liquid which has excellent sealing effect for aluminum oxidation film. It does not contain heavy metals, which not only will solve the problems caused by heavy metal in waste water treatment process, but also can avoid aluminum surface greenish phenomenon which caused by the oxide film absorbing nickel salt during the sealing period. LW-99 is applicable to the transparent film, polishing, electrolytic coloring film sealing and it has the advantages of simple operation, environmental protection, water-saving, free of treatment to fluoride and nickel irons in waste water processing which can be cost-saving.

Features of LW-99:

1) Environmental Protection: Free of nickel, fluoride and heavy metal;

2) Performance: high corrosion resistance and strong light resistance;

3) Odorless: No smell;

4) Innovation:LW-99 is the initiate in China and opens a new era of nickel-free and fluoride-free sealing products;

5) Stability: The environmental aging tests shows that the profiles with LW-99 sealing exposure in the hot sun by several years , their appearances will be very stable (almost no change).