How to control the color difference during aluminium anodizing (一)

How to control the color difference during aluminium anodizing (一)

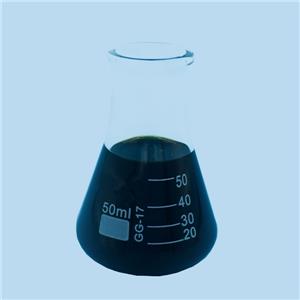

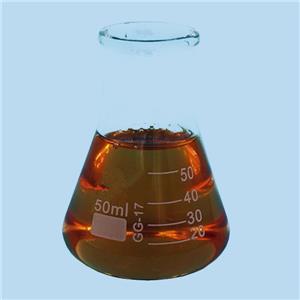

We need to reduce the color difference by controlling coloring bath solution

Firstly , the deionized water must be used when make-up the coloring bath. If it is tin salt, H2SO4 and stabilizer should be added first, and then SnSO4 should be added after full dissolution to prevent the oxidation and hydrolysis of Sn2+; If it is tin and nickel salt, SnSO4 can be added into the nickel salt solution. The composition of the bath solution must also be sampled and analyzed at a certain frequency after the bath solution is prepared,until the normal production process. According to the analysis results and the addition of corresponding agents, the bath solution must be stabilized. The control range of the bath solution must also be stable, and the addition amount must be small and multiple times.

The concentration of each component in the bath solution has a direct impact on the color difference. Generally speaking, the main salt concentration increases, the coloring speed increases, and the color tone deepens; Sulfuric acid is added to the solution in order to maintain the coloring stability. If the concentration is too high, the tank and parts are easy to attach hydroxide. If the concentration is too low, the H+concentration is too high and the competitive reduction will result in a decrease in the coloring speed, or even no coloring; H3BO3 plays a buffering role in the film hole, and tin cannot precipitate without adding boric acid in the tin salt solution, resulting in color difference and dispersion of the profile; Accelerator plays a catalytic role in nickel salt solution to ensure that Ni2+can be precipitated smoothly when the solution pH is about 1, and maintain good color uniformity and stability; The stabilizer is composed of complexing agent, reducing agent, antioxidant and electrode oxidation inhibitor to prevent the oxidation and hydrolysis of stannous oxide and maintain the coloring stability.

Stirring the bath solution is beneficial to the uniformity and reproducibility of color difference. Generally, single nickel salt solution can be stirred with compressed air, but single tin salt or double salt can not be stirred with compressed air. Inert gas can be considered for stirring, or mechanical stirring can be used to prevent the oxidation of stannous ions. Circulating filtration of the color solution is also a way to maintain the stability of the solution.