Two Acids Chemical Polishing Additive

- China

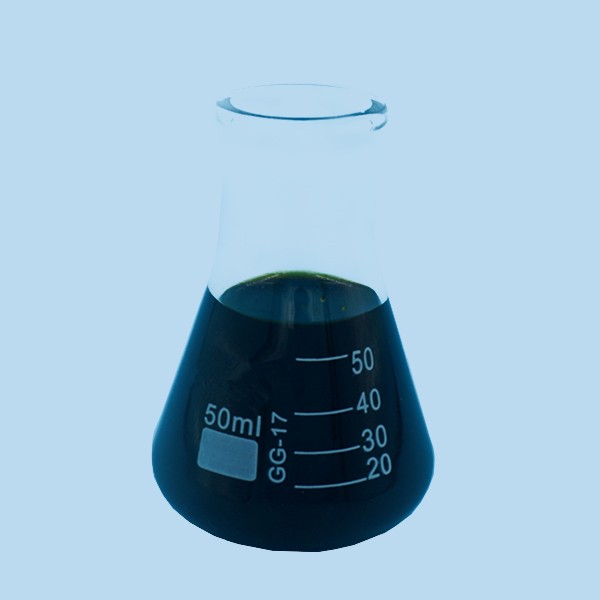

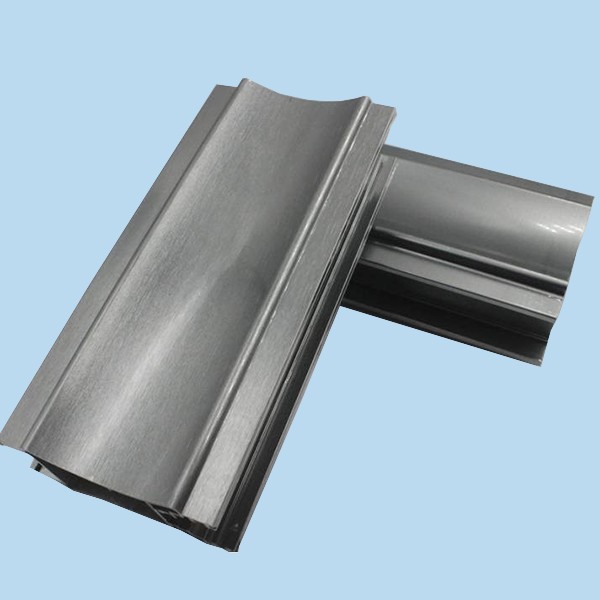

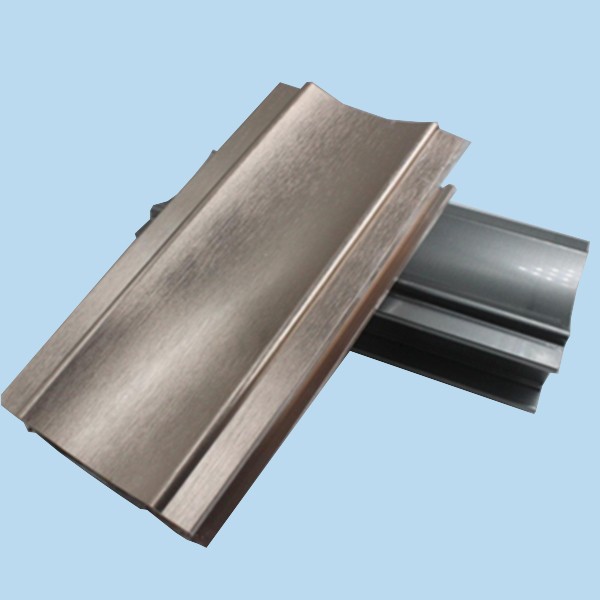

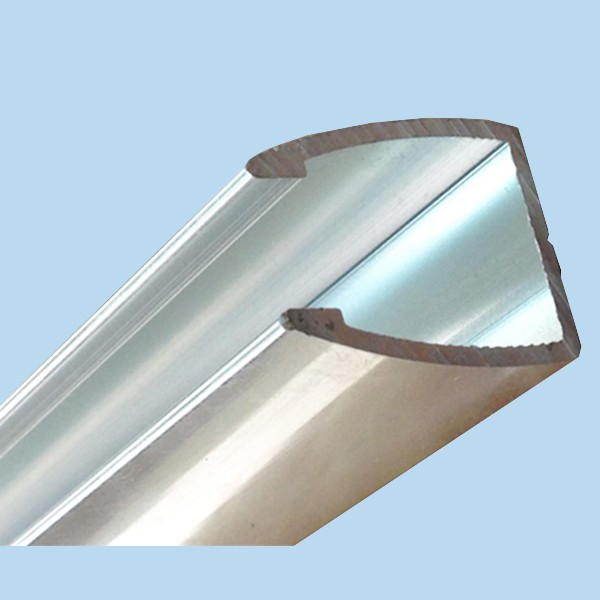

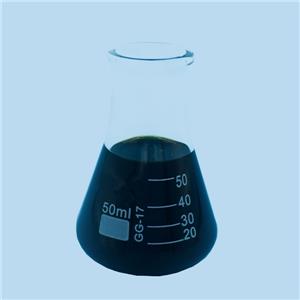

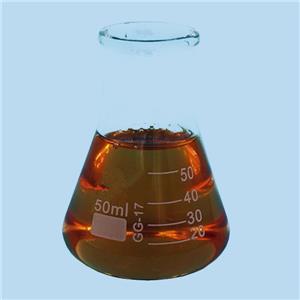

LW-38 chemical polishing additive is a kind of dark brown to black clear liquid and mainly applicable to the aluminum profiles chemical polishing treatment of sanding surface, brushing surface, glossy, mechanical polishing effect, which can make them have similar high gloss and mirror effect comparable to the three acids chemical polishing process.

1. Features:

1) LW-38 chemical polishing additive is green and environment-friendly. It does not contain nitric acid, nitrate and nitrite. Its composition is environmentally friendly, thus, it is smokeless, odorless and does not produce toxic gases when aluminum profiles are in chemical polishing process.

2) LW-38 chemical polishing additive can also achieve a comfortable working environment without any exhaust purification equipment in processing.

3) LW-38 chemical polishing process requires lower processing temperature and makes lower energy consumption than three acids chemical polishing.

2. Bath Make-up:

1) Phosphoric Acid (85%) : Sulphuric Acid (98%) =7:3 bath make-up

Name | Quantity | Unit | Quantity |

LW-38 | 50-70 | kg | |

Phosphoric Acid (85%) | 700L(1190 kg) | ||

Sulphuric Acid (98%) | 300L(552 kg) | ||

Aluminum Chips ( washed cleanly) | 30 | kg | |

2) Phosphoric Acid (85%) : Sulphuric Acid (98%) =1:1 bath make-up

Name | Quantity | Unit | Quantity |

LW-38 | 50-70 | kg | |

Phosphoric Acid (85%) | 500L(850 kg) | ||

Sulphuric Acid (98%) | 500L(920kg) | ||

Aluminum Chips (washed cleanly) | 30 | kg | |

Note: If the bath size is large than 5m3, it is generally recommended to apply the ratio of phosphoric acid (85%) : sulphuric acid (98%) =7:3 for two acids bath make-up; while the bath size is less than 5m3 and the polishing effect requirement is not very high then can apply the ratio of phosphoric acid (85%) : sulphuric acid (98%) =1:1 for two acids bath make-up.

3. Operating Conditions:

1) Phosphoric Acid (85%) : Sulphuric Acid (98%) =7:3 operation conditions

Name | Quantity | Unit |

Polishing Temperature | 80-110 | ℃ |

Polishing Time | 60-360 | s |

Dripping Time | 20-120 | s |

Phosphoric Acid Content | 48-58 | % |

Sulphuric Acid Content | 23-33 | % |

Water Content | 10-16 | % |

2) Phosphoric Acid (85%) : Sulphuric Acid (98%) =1:1 operation conditions

Name | Quantity | Unit |

Polishing Temperature | 80-110 | ℃ |

Polishing Time | 60-360 | s |

Dripping Time | 20-120 | s |

Phosphoric Acid Content | 36-44 | % |

Sulphuric Acid Content | 38-46 | % |

Water Content | 8-12 | % |

4. Solution Maintenance:

The bath solution maintenance of LW-38 is relatively simple:

1) Replenish the phosphoric acid, sulphuric acid and LW-38 by proper bath make-up ratio when the bath solution level gets down (no need to add aluminum chips when replenishment);

2) It is not necessary to analyze the bath solution frequently, but only necessary to analyze the phosphoric acid, sulphuric acid, water and aluminum ions content every few days or when problems occur, and adjust them to the parameter range.

5. Packaging and Storage:

Package: Plastic barrel (25kg/barrel or 1000kg/barrel)

Storage: Suggested to store in cool, dry and well ventilated place; away from fire and heat source.