Surface Treatment Method of All Household Aluminum Profile

Aluminum profile is an important application material in the field of construction and machinery industry. Because of its easy processing, good visual effect and rich surface treatment means, aluminum material is actively adopted by many industries. And what are its treatment methods?

1. Sandblasting

Sand blasting is driven by compressed air to form a high-speed jet beam to spray the sprayed materials (copper ore, quartz sand, emery, iron sand, sea sand) to the surface of the workpiece to be treated at a high speed, so as to change the appearance or shape of the aluminum profile surface.

2. Polishing

Mainly divided into: mechanical polishing, chemical polishing, electrolytic polishing.

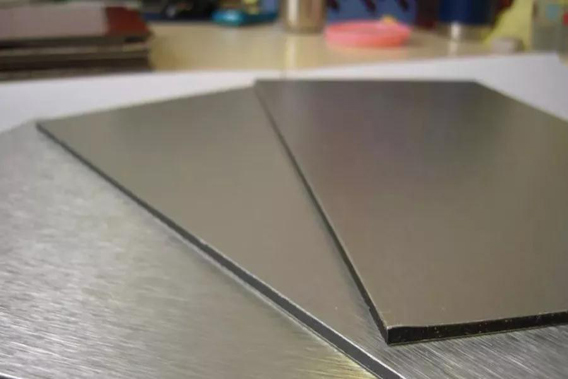

3. Wire drawing

Metal wire drawing is a manufacturing process of repeatedly scraping out the line of aluminum plate with sandpaper. Wire drawing can be divided into straight wire drawing, random wire drawing, spiral wire drawing and thread wire drawing.

4. High gloss cutting

The brightness of the cutting highlight is affected by the speed of the milling bit. The faster the bit speed is, the brighter the cutting highlight will be. On the contrary, the darker the cutting highlight will be and the tool line will be easily produced.

5. Anodic oxidation

Anodic oxidation refers to the electrochemical oxidation of metal or alloy. Under the corresponding electrolyte and specific process conditions, aluminum and its alloy form an oxide film on the aluminum product (anode) due to the action of external current.

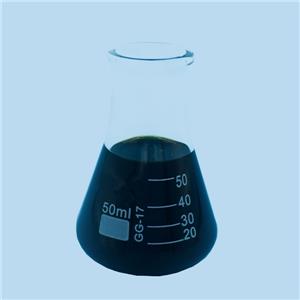

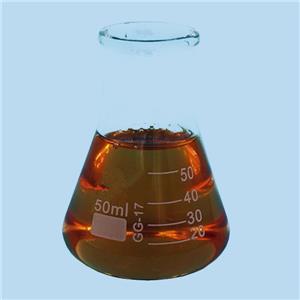

6. Electrophoresis

It can be used for stainless steel, aluminum alloy, etc. it can make products present various colors, keep metallic luster, enhance surface properties, and has good corrosion resistance.

7. Powder coating

It is a dry spraying method, which is used on some metal workpieces by spraying or fluidized bed. The powder is absorbed on the surface of the workpieces by static electricity. When it is completely dry, a protective film will be formed on the surface.

There are other surface treatment methods, which are not listed here~~

All aluminum furniture has the advantages of aluminum alloy, which has a certain strength to ensure that the furniture is not easy to deform in the process of use. In terms of density and pressure, it has good performance, which can effectively ensure that the furniture can be used well in outdoor harsh conditions.

At the same time, in the process of use, because it is relatively light, easy to move, very convenient for use in daily life, at the same time, because of its moderate hardness, when people contact aluminum alloy furniture, it will not produce excellent discomfort.