6063 Aluminum Alloy

6063 Aluminum Alloy

6063 aluminum alloy belongs to the 6000 series, mainly adding magnesium and silicon, with good formability and mechanical properties. The following are the detailed characteristics and applications of 6063 aluminum alloy:

Features

1.Excellent extrudability: 6063 alloy performs well in the extrusion process and is suitable for making profiles of complex shapes.

2.Good surface treatment: Easy to anodize and spray, smooth surface, can obtain a variety of colors and gloss.

3.Moderate strength: Compared with other aluminum alloys, 6063 has good strength and ductility, suitable for a variety of applications.

4.Corrosion resistance: Good resistance to environmental corrosion, suitable for outdoor applications.

Applications

-Building materials: Widely used in building structures such as window frames, door frames and curtain walls.

-Furniture manufacturing: Used to make aluminum alloy furniture such as tables, chairs and shelves.

-Transportation vehicles: Structural parts used in automobiles and public transportation.

-Electrical appliances: Can be used to manufacture various electrical housings and structural components.

Technical Parameters

- Tensile Strength: Usually between 180-310 MPa.

- Elongation: Can reach 8%-12%, making it more flexible during processing.

6063 aluminum alloy is widely used in many fields due to its excellent performance and adaptability. Here are some specific application cases and related technical data:

Application Cases

1. Building Materials

-Window Frames and Door Frames: 6063 aluminum alloy is used to make high-strength, lightweight windows and doors with good thermal and sound insulation properties.

-Curtain Wall: In modern buildings, 6063 alloy is often used in curtain wall systems, providing an elegant appearance and good weather resistance.

2.Furniture

- Office Desks and Chairs: Office furniture using 6063 aluminum alloy is both beautiful and durable, suitable for modern office environments.

- Display Racks: Display racks used in retail stores and exhibitions, providing stable support and easy assembly.

3. Transportation

- Automobiles: 6063 alloy can be used to manufacture the body frame, doors and interior parts of automobiles to reduce weight and improve fuel efficiency.

-Public Transportation: Used in the structural components of buses and trains to improve overall performance and safety.

4. Electrical Appliances

-Housings and Brackets: Used in the housings and brackets of electrical appliances, providing strength and heat dissipation performance, commonly found in equipment such as televisions and air conditioners.

Technical data

- Alloy composition:

- Silicon (Si): 0.2-0.6%

- Magnesium (Mg): 0.45-0.9%

- Iron (Fe): ≤0.35%

- Copper (Cu): ≤0.1%

- Manganese (Mn): ≤0.1%

- Zinc (Zn): ≤0.1%

- Aluminum (Al): Balance

- Mechanical properties:

- Tensile strength: 180-310 MPa

- Yield strength: 130-250 MPa

- Elongation: 8%-12%

- Brinell hardness: Generally 60-80 HB

- Heat treatment:

- Natural aging: 6063 alloy is not suitable for heat treatment strengthening, and strength is usually improved by natural aging or cold working.

-Surface treatment:

- Easy to anodize and paint, anodizing can obtain better corrosion resistance and appearance.

Summary

6063 aluminum alloy is suitable for a variety of applications due to its excellent formability and surface treatment characteristics, especially in the fields of construction and furniture.

Our materials are all made of 6063 material:

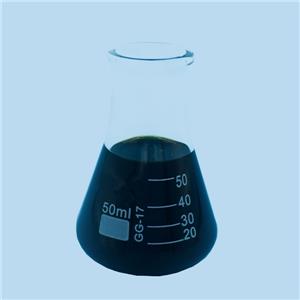

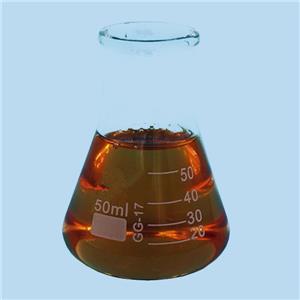

LW-16 Brightening and Cleaning Additive