Aluminum Industry's Knowledge & Types of Aluminum Alloy

Aluminum Industry's Knowledge & Types of Aluminum Alloy

The technical knowledge points of the aluminum industry include the following aspects:

1. Properties of aluminum:

- Lightweight, high strength, corrosion resistance.

- Good electrical and thermal conductivity.

2. Aluminum alloys:

- Common aluminum alloy series include 1000 series (pure aluminum), 2000 series (copper alloy), 3000 series (manganese alloy), 4000 series (silicon alloy), 5000 series (magnesium alloy), 6000 series (magnesium and silicon alloy), 7000 series (zinc alloy), etc.

- Each series has different mechanical properties and application areas.

3. Aluminum processing methods:

- Casting: Aluminum parts of various shapes are made by casting aluminum alloys.

- Extrusion: Aluminum alloys are extruded through a die, often used to make profiles.

- Stamping and forming: used to make thin plates and parts.

4. Heat treatment:

- Heat treatment processes can improve the mechanical properties of aluminum alloys, such as aging treatment, annealing, etc.

5. Surface treatment:

- Surface treatment technologies such as anodizing, spraying and electroplating can improve the corrosion resistance and aesthetics of aluminum.

6. Welding and joining:

- Aluminum welding technologies include argon arc welding (TIG), MIG welding, etc. When welding, attention should be paid to the high thermal conductivity and oxide film of aluminum.

7. Recycling and sustainability:

- Aluminum has good recyclability, and the energy consumption of recycled aluminum is only 5% of that of original aluminum, which helps to reduce environmental impact.

Aluminum alloy is an alloy of aluminum and other elements (such as copper, magnesium, manganese, silicon, zinc, etc.), which has excellent mechanical properties and processing properties. According to the main alloying elements, aluminum alloys can be divided into the following series:

1. 1000 series (pure aluminum)

- Main component: Aluminum content is above 99%.

- Features: Good conductivity, corrosion resistance and formability, but low strength.

- Application: Cables, conductors, chemical equipment, etc.

2. 2000 series (copper alloy)

- Main component: Mainly copper is added (such as 2024 alloy).

- Features: High strength, good wear resistance, but poor corrosion resistance, usually requires surface treatment.

- Application: Structural parts in the aerospace, military and transportation industries.

3. 3000 series (manganese alloy)

- Main component: Mainly manganese is added (such as 3003 alloy).

- Features: Good formability and weldability, moderate strength, good corrosion resistance.

- Application: Containers, building materials, etc. for food and chemical industries.

4. 4000 series (silicon alloy)

- Main ingredients: Mainly add silicon (such as 4045 alloy).

- Features: Low melting point, good fluidity, suitable for welding and casting.

- Application: Welding wire, automotive parts, heat exchangers, etc.

5. 5000 series (magnesium alloy)

- Main ingredients: Mainly add magnesium (such as 5052 alloy).

-Features: High strength, good corrosion resistance and weldability, especially suitable for marine environment.

- Application: Ships, automobiles, pressure vessels, etc.

6. 6000 series (magnesium and silicon alloy)

- Main ingredients: Mainly add magnesium and silicon (such as 6061 alloy).

- Features: Good mechanical properties, easy to process and weld, good corrosion resistance.

- Application: building structures, transportation, mechanical parts, etc.

7. 7000 series (zinc alloy)

- Main ingredients: mainly zinc (such as 7075 alloy).

- Features: extremely high strength, poor corrosion resistance, usually requires surface treatment.

- Application: occasions with high strength requirements such as aerospace, sports equipment, etc.

Alloy design and selection

-Design considerations: select the appropriate aluminum alloy according to the use environment, mechanical properties requirements and processing methods.

-Standards and specifications: Common standards such as ASTM, EN, GB, etc. provide regulations on alloy composition and properties.

Future trends

-New alloys: Researchers are developing lighter and stronger aluminum alloys to meet the needs of aerospace, electric vehicles and other fields.

- Sustainability: The research and development of recycled aluminum alloys is also constantly advancing to reduce the impact on the environment.

Here are our main recommended products:

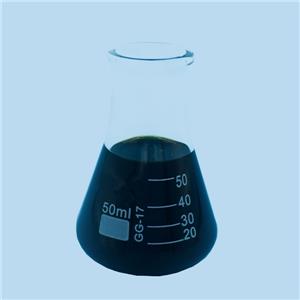

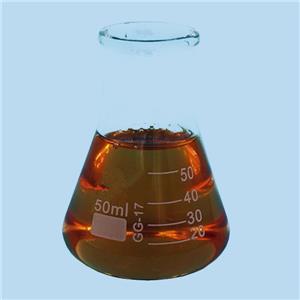

LW-14 Chromium-free Degreasing Additive

LW-19 Chromium-free Passivation Additive

LW-53 Sn Salt Electrolytic Coloring Additive