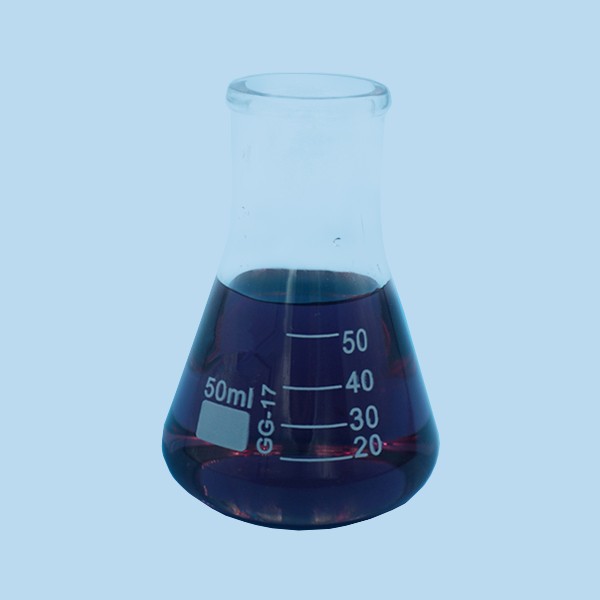

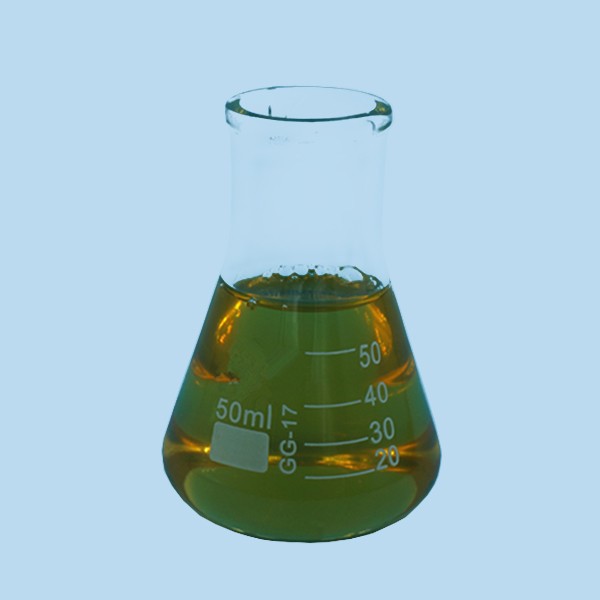

Liquid Medium Temperature Sealing Additve

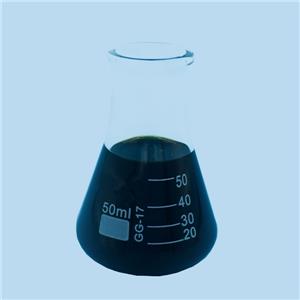

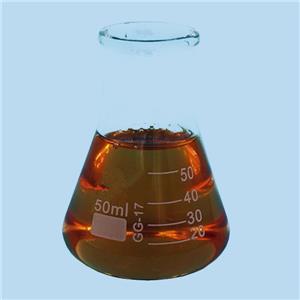

LW-10 Medium Temperature Sealing Additive is a reddish brown to brown liquid which is for aluminum profiles oxidation film sealing treatment, the sealing quality is stable and of wide application range, the profile surface texture is superior after sealing treatment.

1.Bath Make-up:

Name | Quantity | Unit |

LW-10 | 10 | g/L |

Nickel Acetate | 5 | g/L |

Deionized Water | Balance | |

2.Operating Conditions:

Name | Quantity | Unit |

Ni2+ | 1-1.6 | g/L |

PH | 5.5-6.2 | |

Temperature | 60±5 | ℃ |

Time | 1μm/min | |

3. Characteristics:

1) Fast sealing speed: for thick oxidation film aluminum profiles (15-20μm), 13-15 mins is enough for sealing.

2) Excellent anti-sealing bloom capacity: LW-10 contains high polymer ash inhibitor, even in high temperature and high PH value is not easy to form bloom.

3) No iridescence and no color fading for black aluminum profiles.

4) Especially suitable for aluminum solar frame products.

4. Solution Maintenance:

1) Analyze the concentration of Ni2+. Make it fluctuate in a small range.

2) The heating device is recommended to install on the bath walls but not at the bottom, because after long time use some water scales will be generated and deposited on the heating tubes, which will reduce heating performance and make it difficult to clean the precipitations.

3) If PH drops during the production, should adjust PH with ammonia water or triethanolamine.

4) Replenish the nickel acetate and LW-10 with the scale of 1:1.5 according to the analysis result.

5) The PH of rinsing bath should be strictly controlled to be higher than 4.5.

5. Packaging and Storage:

Package: Plastic barrel (25kg/barrel,1000kg/barrel)

Storage: Suggested to store in cool, dry and well ventilated place; away from fire and heat source.