Silane Ceramic Film-forming Additive

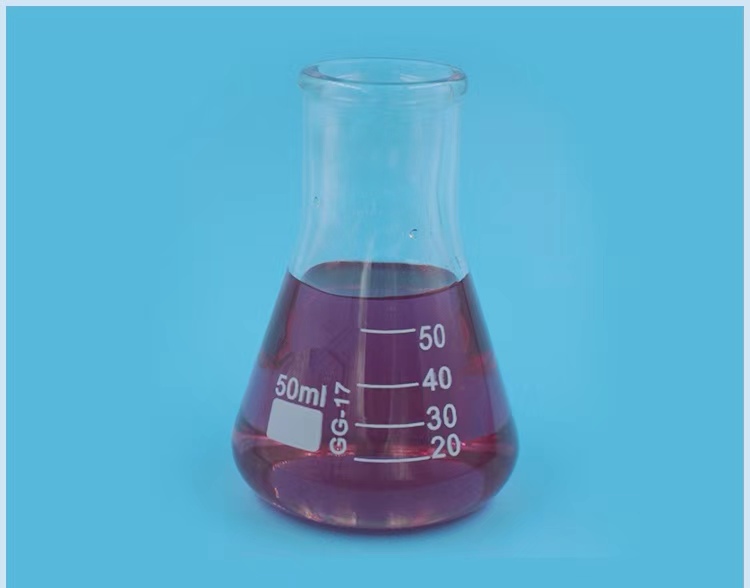

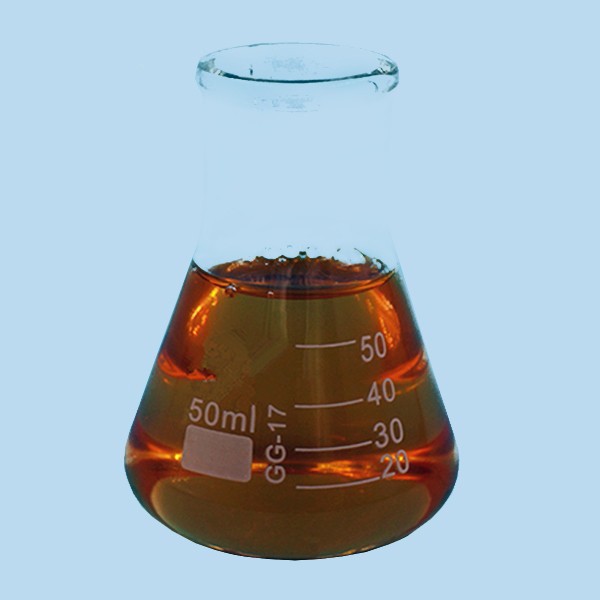

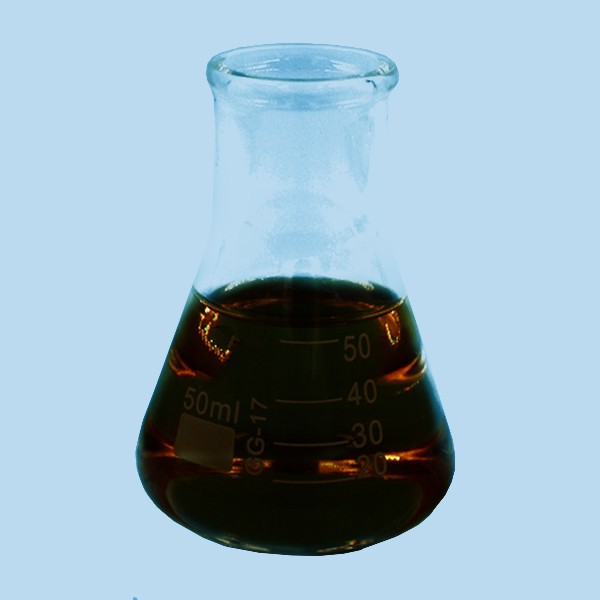

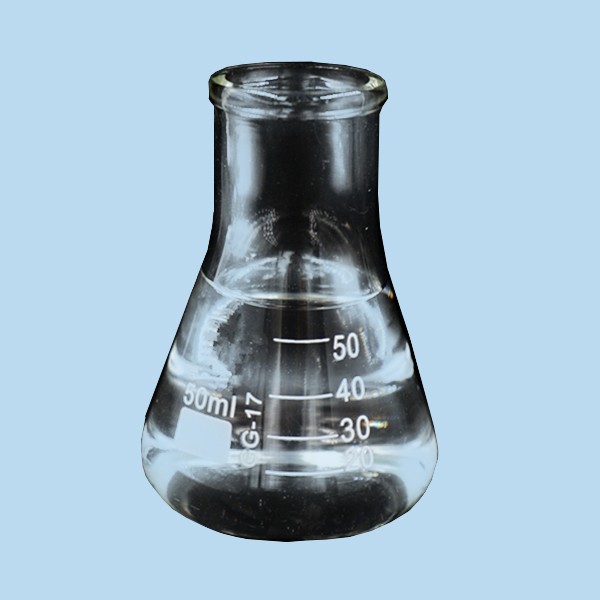

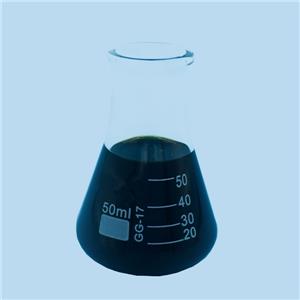

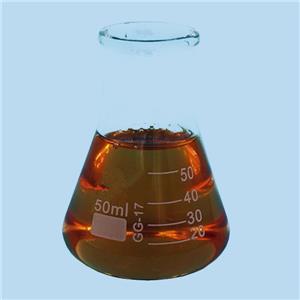

LW-161 Silane Ceramic Film-forming Additive is a kind of liquid single component environmentally friendly pink transparent, non-phosphorus, non-phosphorus, nickel and other heavy metals, especially suitable for surface ceramic treatment of steel, galvanized parts, aluminum and magnesium and other metal substrates, can enhance the bonding force of coating and corrosion resistance, it can replace iron-based phosphating and chromium treatment processes.

Technical features:

1. It has excellent antirust performance of transition section and is suitable for acid pickling lines.

2. Excellent coating performance, good adhesion, and excellent salt spray performance. The neutral salt spray after powder spraying can reach 720-1000 hours. Neutral salt spray after electrophoresis can last up to 500 hours.

3. Excellent compatibility of various coatings (domestic and imported)

4. During the operation of the bath, almost no waste residue is produced.

5. Long replacement cycle (more than 12 months)

6. After ceramicization, it can be dried and coated directly without washing with water.

Instructions:

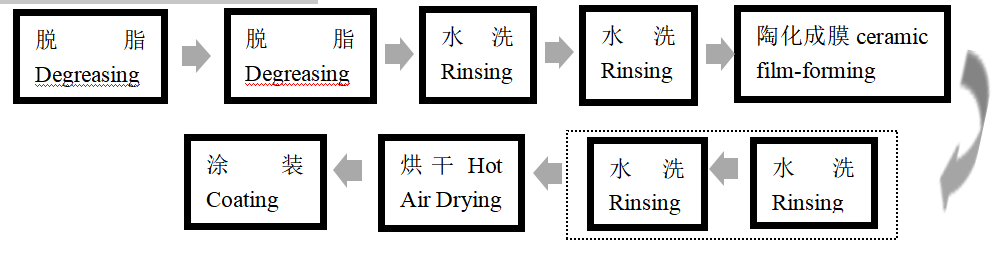

1、Operating Process :

2、Make-up:

Before arranging the tank, make sure the tank is clean and free of dirt or other chemical residues. In order to increase the service life of the ceramic bath liquid, it is recommended to use pure water (conductivity <30us/cm) to prepare the bath. For every 1000 liters of bath liquid, add 10 kg of LW-161, and then adjust the pH value of the bath liquid to 2.0-4.0. After the bath liquid is mixed evenly, it can be used.

3、Operating Conditions:

Name | Quantity | Unit |

LW-161 | 5-20 | g/L |

Temperature | 15-40.0 | ℃ |

Time | 90 - 180s (immersion); 30-120s (spray) | |

Pressure | 0 - 1.0 bar (spray) | |

PH | 2.0-4.0 | |

4、Equipment requirements: All equipment that comes into contact with LW-161 is required to be stainless steel (316L) or lined with PVC, PVDF, PTFE or PE.

5、Packaging and storage: 25kg/barrel. It is recommended that the product be stored in a ventilated and dry environment at 5-40℃.

6、Labor and environmental protection: Relevant laws and regulations must be followed for the transportation, storage, use and disposal of three wastes of concentrated or diluted solutions of chemicals (such as tank solutions).

7、Wastewater Discharge: All wastewater treatment related to the transportation, storage, use and concentration or dilution of chemicals, or pollutants from baths, by-products and processes must be handled in compliance with international and local regulations. All wastewater must be treated in compliance with international and local regulations before being discharged to sewers.